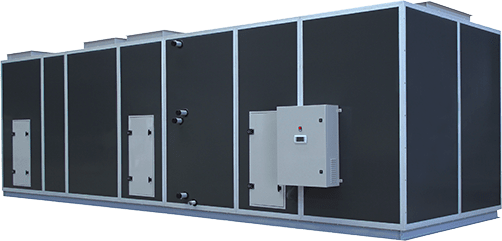

High efficient all-condition tunnel built-in air conditioning system

1. Cancel of the cooling tower

Cancel the cooling towers, saving the floor spaces, saving equipment costs, reducing energy consumption for operation, the device is fitted in the tunnel to avoid the impact of noise pollution and health risks, providing harmonious urban environment.

2. Tunnel installation, cost savings

Evaporative condenser is installed in the subway tunnels, save floor space, reduce civil excavation area, save construction investment costs

3. Annual energy saving operation

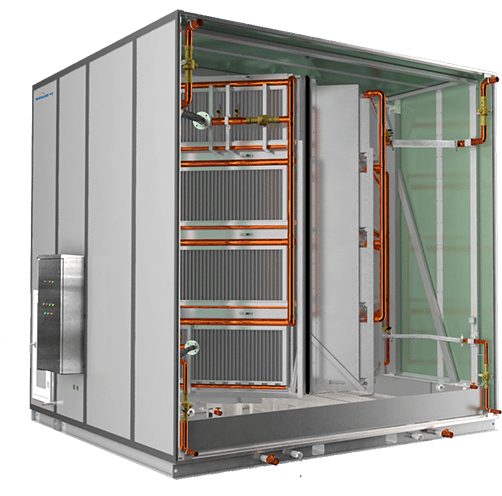

- In use of the independent innovation developed new serpentine tube condenser, using water evaporation latent heat to take away the heat of condensation, good performance of heat dissipation, lower condensing temperatures, EER up to 4.5 or more, reduce operating costs .

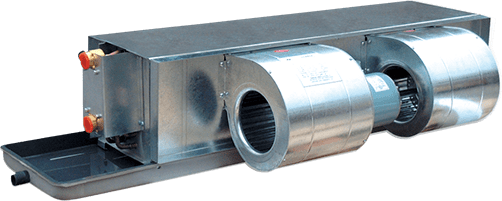

- Ventilation and air conditioning systems can be chilled water or direct evaporation type, reduce the times of system heat exchange, reduce energy loss, actual energy saving.

- On ventilation mode, to turn on the heat exchanger to reduce the operation resistances, implementation of energy efficient.

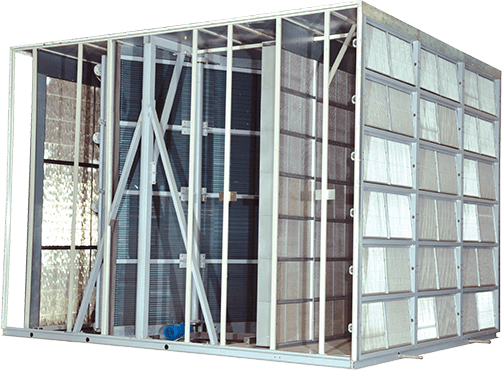

4. Perfect combination of evaporative condensate device and civil engineering

Evaporative condensate device with the construction installation realize the seamless docking; During the fire disaster, the heat exchanger can be rotated to open, to achieve the fire protection function; Easy maintenance, reduce resistance, and achieve energy saving.

5. Automatic, intelligent & safe

- Can be selected automatically as small fresh air mode, total fresh air mode, ventilation mode according to indoor and outdoor conditions, to realize the fully automated control and energy efficient operation.

- Intelligent control system that can provide the dual control for remote and local control to achieve the users’ remote control, easy for real-time control of the unit status and can be controlled at any time;

- Various parameters and operating status can be automatically monitored for unit operation, provide alarm information, and provide common methods for trouble shooting, to ensure safe operation of equipment.。

6.Evaporative Condensate anti-corrosion, anti-fouling

- Anti-corrosion: Serpentine tube evaporative condenser uses unique technology, greatly enhance the heat transfer coefficient, and in use of 304 stainless steel, highly corrosion and hydrophilic properties, durability; Configuration with water treatment device, water can be treated to the standard demineralized water, greatly reducing the possibility of fouling.

- Anti-fouling: Evaporative condensate device descaling, use the latest dynamic descaling technology, use automatic mechanical descaling devices, as well as automatic sewage systems to ensure high-quality water source; Use patented descaling technology, long service life for evaporative condensate heat exchanger, high efficiency for heat exchange, simple and efficient, low cost for use and maintenance.

7. Flexible installation

Compact unit structure, subway station tunnel installation, and easy for installation.